Single Layer PCBs vs 2 Layer PCBs vs Multi-Layer PCB (4 Layer PCBs/ 6 Layers PCB) Plus, wn e have fabrication drawings, assembly drawings, notes, quality, and test specifications. Plus, there are other documents like Gerber data, the schematic, BOM, CAD data, etc. In the long run, all PCB design layers require assembly documentation. So, designers need this info because the PCB connects functional parts to PCB traces. They should also know the difference between mechanical and electrical assembly rules.ĭesigners must also check if the physical component mounting reaches its mechanical requirements. So, the design teams must focus on thermal, signal management, etc. Plus, the assembly information helps to regulate the location and mounting of electronic devices.Īlso, the assembly process entails that design teams focus on the following. They also help to provide PCB foundational measurements. Of course, their obvious function is describing the dimension and mechanical layer. Trace Dimensionsĭimension lines and markings have their uses in a PCB. And it’s even better if it’s for high-frequency signals. It also does an excellent job for the circuit’s integrity. Mainly for different signal pairs, it solidifies the PCB stability. Plus, it affects the power plane’s thermal conductivity.įurthermore, merging the copper’s length and thickness helps to do something. The quality of copper in a PCB impacts the impedance of a ground plane. Also, it helps to describe the amount of current loss. Of course, it influences the capacity of the PCB to attain the right amount of current flow. The various weight and thickness of copper in a PCB impacts too.

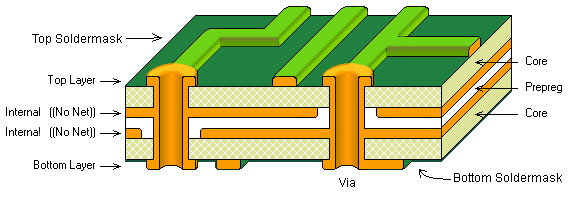

Every engineer knows it acts as a great conductor. The function of copper in a PCB is pretty apparent. Also, it monitors the constant impedance over an extensive frequency range. The stability of a PCB highly depends on the steady impedance of dielectric materials. The dielectric materials help to isolate signals on adjacent PCB layers.Ģ. And all that happens as the PCBs run rapid signals.ġ. The dielectric materials offer two critical functions for PCBs. And it’s the trace dimensions aligned with the dimension or mechanical layer. So, they include the copper, the dielectric material, and one more thing. Let’s face it, PCB layers are the foundation blocks of a PCB. Plus, they have printed openings with a subtractive photographic procedure. Furthemore, the solder masks get applied either as liquid or as a sheet on the PCB layers. And you can find the solder masks on both the top and bottom copper layers. Generally, regular PCBs consist of solder masks on the outer copper layer. But RF boards have teflon based substrates. Most times, it’s before the etching of the circuit pattern.

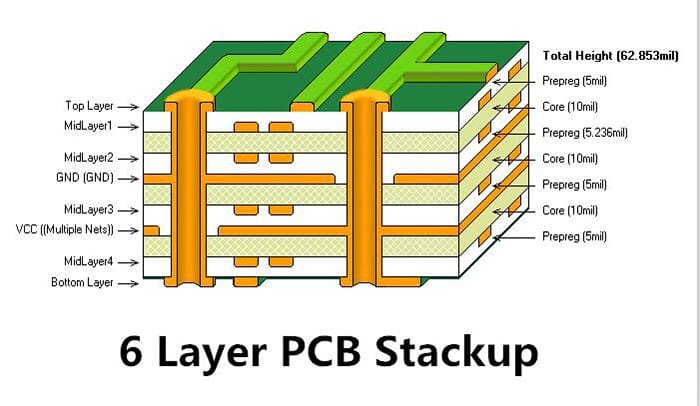

Also, it’s the epoxy saturated fiberglass meted on an adhered tough copper sheet. And this substrate is the FR4 (Fire Retardant Version4). In the middle of each layer, there’s an insulated substrate. And the same thing applies for other PCB layers. For a 4 layer PCb, for instance, you’ll find a top, inner 1, inner 2, and bottom layer. Hence, you’ll find a 2 Layer PCB having a top and bottom layer. What Are the Layers of a PCB?įirst off, before we dive deeper into PCB layers, let’s have a clear understanding of “layers.” These layers are responsible for assembly or building a PCB.Ī layer is the signal conducting levels that are vertical to the PCB plane. That’s why we curated an ultimate FAQ guide to help your understanding of PCB layers.Īre you ready? Let’s go deeper! 1. Plus, a PCB needs a solid shaping principle too. So, the same thing applies to PCB layers for building electronic appliances. Afterward, the builder establishes the walls, doors, windows, etc. That’s why a building engineer focuses on the foundation first. Hence, it requires a well-structured layered approach. Constructing a house should start from the foundation up. So, designing a tech device without considering PCB layers is incomplete.Ĭan you imagine constructing a house from the roof? Do you have loads of questions to ask about PCB layers? If yes, you’re in the right place.

0 kommentar(er)

0 kommentar(er)